check aircraft oxygen bottle for hydrostatic test date|hydrostatic cylinder testing : white label Check hydrostatic dates on all cylinders, especially those that are to be filled on the aircraft. If a cylinder is out of date, remove and replace it with a specified unit that is serviceable. Check pressures on all cylinders on the cart and in the .

WEBSão Luiz. About. Recopa Gaúcha is a professional football league in Brazil. The current holder of the title is Grêmio and the team that holds the most titles is Grêmio. Sofascore tracks live football scores and Recopa Gaúcha table, results, statistics and top scorers.

{plog:ftitle_list}

Resultado da A Terceira Divisão do Campeonato Chileno de Futebol de 2020 (oficialmente Campeonato de Segunda División 2020) é a 10ª edição da Segunda División, um campeonato de clubes equivalente à terceira divisão do futebol chileno. [1] A competição é organizada pela Associação Nacional de Futebol .

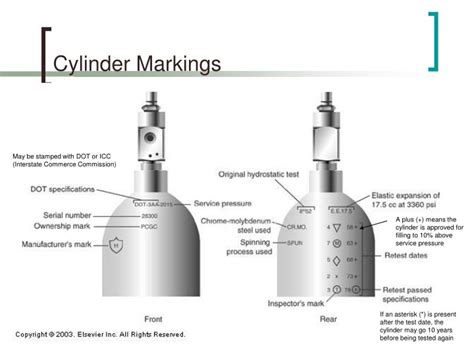

See current exemption or special permit. 5 (see §§180.209 (l) and 180.213 (d) (2)). Hydrostatic testing is often required at certain intervals for Aircraft Oxygen Cylinders, Fire Extinguishers and Pneumatic Bottles. The interval at which .How to Read Hydro Test Date Markings. How to Read Manufacture Date Markings. How to Read DOT Cylinder Specifications. Hydrostatic Testing Intervals for Aviation Cylinders – Oxygen .Records must include: Date of inspection (month and year); DOT-specification number; cylinder identification (registered symbol and serial number, date of manufacture, and owner); type of .

The hydrostatic test date and inspector mark indicate when the cylinder was last tested and who tested the cylinder. Most oxygen cylinders are required to be tested every 5 years. This test .

oxygen cylinder testing requirements

The stringent quality standards found in aviation are applied to every hydrostatic test we perform, at a price competitive even in the commercial, SCUBA, SCBA, and medical .Check hydrostatic dates on all cylinders, especially those that are to be filled on the aircraft. If a cylinder is out of date, remove and replace it with a specified unit that is serviceable. Check pressures on all cylinders on the cart and in the .To verify that your cylinders are not out of their scheduled hydrostatic due dates, look for the test dates stamped or labeled on them. At Aerospace Services and Products, we provide thorough aircraft oxygen bottle inspections, .Which includes: test number, manufacturers date, serial number, manufacturer, size of bottle, and pre-determined test pressure (test pressure is typically 5/3 operating pressure). 3) .

The hydrostatic test date will be stamped on the side of the cylinder along with other markings like the manufacture date and serial number. Other cylinders such as steel or composite have different service life and .The placard must be covered with a coat of clear epoxy when additional information is added, such as a new hydrostatic test date. Oxygen cylinders are considered empty when the pressure inside drops below 50 psi.

Services We Provide . Function testing of aircraft oxygen components. Repair services / Overhauls. Hydrostatic testing of cylinders. FAA Form 8130-3 certificationThe cylinder may be proof pressure tested. The test is successful if the cylinder, when examined under test pressure, does not display a defect described in § 180.205(j)(1)(ii) or . Upon successful completion of the test and inspection, the cylinder must be marked in .

Check out the link for the current rev. or give Andrew a call. Have your mechanic remove and ship us your bottle. Andrew has been an A&P mechanic for 26 years and will perform every Aviation Oxygen cylinder Hydro test personally. We know aluminum, steel, hoop wrapped and fiber wound aviation cylinders. We have the proper equipment to test them . Ensuring Scuba Tank Safety: Read The Hydrostatic Test Date! It is critical to be aware of the date of a hydrostatic test for a scuba tank. When a cylinder passes inspection, it is stamped with a date, and after three, five, or ten years, it is time to do another hydro test. To ensure the tank’s safety, make sure the test date is accurate.

Halon Recycling. 1301 Halon Recycling. Recovering as much Halon as possible has always been the objective of Aerospace Turbine Rotables, and now with the newest technology the total amount of recovery and the quality of Halon 1301 that can be recovered, filtered, and reused meeting MIL-M-12218C and ISO 7201 is industry standard setting. In addition, Aerospace .Hydrostatic oxygen cylinder testing can ensure your equipment won’t let you down when you need it most in high altitudes. Hydrostatic Testing for Inflatable Cylinders. Emergency inflatable cylinders, which deploy slides during an emergency evacuation, or rafts and helicopter floats during a water emergency, also require hydrostatic testing. In the world of portable aviator’s oxygen tanks, the DOT regulations govern not specifically the transportation of oxygen-filled cylinders, but things like hydrostatic testing, cylinder life limits and even the specific nomenclature marked on the cylinders—which is what refilling stations have been trained to look for before refilling them.

oxygen mask until the other pilot has returned to that crew-member’s station. Sec. 135.89 Pilot requirements: Use of Oxygen. (a) Unpressurized aircraft. Each pilot of an unpressurized aircraft . shall use oxygen continuously when flying— (1) .

This testing is required by the DOT to ensure the continued safety of the cylinder. During a hydrostatic test, the cylinder is visually inspected for stress cracks and corrosion and is pressurized .HYDROSTATIC TESTING OF CYLINDERS Aviasafe aviation MRO is proud to present it’s new dot approved Hydrostatic testing facility for various DOT rated cylinders. Hydrostatic Testing of Cylinders is the most widely recognized technique utilized for testing Cylinders. . We are currently able to do various cylinder like Aircraft Oxygen Cylinder .Subsequent hydrostatic test dates are also stamped there as well. Composite cylinders use placards rather than stamping. The placard must be covered with a coat of clear epoxy when additional information is added, such as a new hydrostatic test date. Oxygen cylinders are considered empty when the pressure inside drops below 50 psi.

These cylinders are preferred by many who build the state-of-the-art composite-fiber aircraft. They are made under a special permit, DOT SP 8162. If used in commercial applications or in a type-certified aircraft, the DOT service life is 15 years from date of manufacture (first hydro-test date) and hydro tests are required every 5 years.Hydrostatic Testing Aircraft Pressure Vessels February 2018. What is hydrostatic testing and why must it be done? Hydrostatic testing is a process to determine the strength and integrity of pressurized vessels. These include, but are not limited to; oxygen cylinders, fire bottles, emergency air bottles, reservoirs, and water bottles. On composite cylinders, you’ll find the RIN on an epoxied sticker. Note that you cannot charge any cylinder after the hydrostatic expiration date. Survival equipment: If you have composite cylinders, you’ll have an epoxied sticker displaying the RIN on the cylinder. Check the maintenance record to find the re-test interval for slide assemblies. Below is a PDF that should answer most of the questions that you might have as well as help identify the testing interval for your cylinder. Hydro Testing of Aviation Cylinders Size : 950 kB Format : PDF. That helps, but .

The hydro test is not an FAA requirement (unless it is in the ICA for the bottle). It can be done anywhere. The local cylinder shop charges about to do a hydro test. Most large cities have hydro test facilities. Think of all those .

Hydrostatic Testing. Aerox provides DOT Hydrostatic testing services of your portable and on-board aviation Oxygen cylinders. Ship to Aerox’s main facility at 12871 Trade Way Drive, Suite 8 in Bonita Springs FL, 34135. Aerox works .

The gas bottle test date has a plus and a star after the 12 – 91 date. And that shows that in the test the bottle was good for a ten percent overfill. And the Argon tank didn’t need testing till Dec 2001.Hydrostatic testing. Hydrostatic testing is an essential part of quality control and is the industry standard for most testing. These tests are performed to determine the safety and structural integrity of a variety of objects including gas cylinders, storage tanks, plumbing systems and chemical pipelines.The United States Department of Transportation (DOT) requires that all aircraft oxygen cylinders undergo hydrostatic testing regularly to ensure that they can operate under high-pressure conditions and are free of stress cracks and corrosion. Different types of oxygen cylinders require different testing frequencies and service life requirements:

manufacture & supplier of mullen burst strength tester

manufacturer of mullen burst strength tester

Auto service and support packages available! MES specializes in the hydro-testing and recertification of your SCBA and DOT storage cylinders. As the nation’s largest fire equipment distributor and servicing company, MES has 17 in-house service centers staffed with certified technicians trained to meet DOT requirements.Contact our experts at Fire King today to learn more about the benefits of routine hydrostatic cylinder testing. Hydrostatic Cylinder Testing. DOT regulations require periodic hydrostatic testing of high-pressure cylinders. For instance, high-pressure cylinders need a hydrostatic test every five or 10 years, depending on their markings.

The expiry date of an oxygen cylinder is the date after which it’s no longer safe to use. This date is usually stamped on the cylinder’s shoulder or neck and is indicated by a month and year. It’s essential to note that the expiry date is different from the hydrostatic test date, which checks the cylinder’s integrity.

Unlocking the Power of Precision: Hydrostatic Cylinder Testing ensures safety and reliability of pressure vessels. Explore the significance of ASME hydrostatic testing, its procedures, and compliance with regulatory standards. Discover how visual inspection and leak tests ensure structural integrity. Learn the advantages and limitations of hydrostatic testing .We can leak check and service your aircraft air conditioner with R-12 and R134a refrigerant. Our A/C service includes leak checking with a heated A/C Leak Detection Probe. . We can only service aviation O2 bottles that are up to date with a hydrostatic test. We cannot fill medical oxygen bottles. We only use fresh Aviator's Breathing oxygen.

partially charged on the due date of their hydrostatic test may remain in service beyond the test date providing that the cylinder is retested prior to . Fkriod Check Feriod . Oxyqen, Chapter 35 Bottle - Oqgen Portable (DOT-3A) 5 . or . 10 . . and (e)(lSL) Bottle - Oxygen Crew (DOT-3E3T) 3 years* (See 49 CFR, Section Bottle - Oxygen .OXYGEN, FIRE, AND PNEUMATIC BOTTLES FOR EVERY AIRCRAFT We hydrostatically test, repair, and overhaul compressed gas systems for fixed and rotary wing aircraft used in commercial, corporate, military, and general aviation Search Our Capabilities ZERO AOG FEES AND ZERO TIME EXCHANGES

oxygen cylinder testing markings

oxygen cylinder retest date

WEBPinnacle USA, Inc. (239) 734-3443. pinnaclepoolandspa.com. You could be the first review for Pinnacle USA, Inc. Read homeowners reviews before hiring the Swimming Pool Builder or Contractor to help with your project in Naples. If you have questions, read other homeowners’ reviews or our discussion forum for a second opinion.

check aircraft oxygen bottle for hydrostatic test date|hydrostatic cylinder testing